|

Type |

Rated voltage combination |

Connection symbol |

No-load Current(%) |

No-load Loss (KW) |

Load Loss(KW) |

Impedance voltage(%) |

||

|

H.V(KV) |

Tapping range of HV(%) |

L.V(KV) |

||||||

|

SC18-30 |

|

±2×2.5 |

0.4 |

|

2.5 |

0.105 |

0.64 |

4 |

|

SC18-50 |

|

|

2.2 |

0.155 |

0.9 |

|||

|

SC18-80 |

|

|

2.1 |

0.21 |

1.24 |

|||

|

SC18-100 |

|

|

1.9 |

0.23 |

1.415 |

|||

|

SC18-125 |

|

|

1.7 |

0.27 |

1.665 |

|||

|

SC18-160 |

|

|

1.7 |

0.31 |

1.915 |

|||

|

SC(B)18-200 |

|

|

1.5 |

0.36 |

2.275 |

|||

|

SC(B)18-250 |

6 |

|

1.5 |

0.415 |

2.485 |

|||

|

SC(B)18-315 |

6.3 |

|

1.3 |

0.51 |

3.125 |

|||

|

SC(B)18-400 |

10 |

Dyn11 |

1.3 |

0.57 |

3.59 |

|||

|

SC(B)18-500 |

10.5 |

Yyn0 |

1.3 |

0.67 |

4.39 |

|||

|

SC(B)18-630 |

11 |

|

1.2 |

0.775 |

5.29 |

|||

|

SC(B)18-630 |

|

|

1.2 |

0.75 |

5.365 |

6 |

||

|

SC(B)18-800 |

|

|

1.2 |

0.875 |

6.265 |

|||

|

SC(B)18-1000 |

|

|

1.0 |

1.02 |

7.315 |

|||

|

SC(B)18-1250 |

|

|

1.0 |

1.205 |

8.72 |

|||

|

SC(B)18-1600 |

|

|

1.0 |

1.415 |

10.555 |

|||

|

SC(B)18-2000 |

|

|

0.9 |

1.76 |

13.005 |

|||

|

SC(B)18-2500 |

|

|

0.9 |

2.08 |

15.445 |

|||

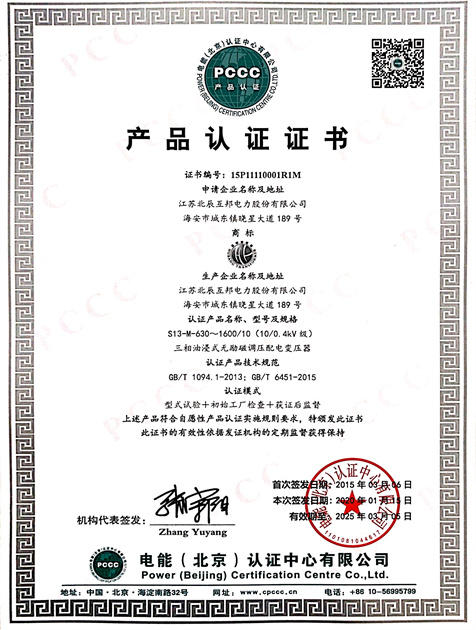

SC(B)18 Three-Phase Resin-Insulated Dry Type Power Transformer

About HUBANG

Jiangsu Beichen Hubang Electric Power Co., Ltd. is a professional manufacturer with 16 years of transformer manufacturing experience.

Our Company is China Dry type transformer Suppliers and Dry Type Power Transformer Manufacturers. In order to better respond to the market situation, vigorously invest in silicon steel production projects, as the upstream product of transformers, silicon steel production and manufacturing project Silicon steel production and manufacturing project will be completed in two phases, the of the project has been tested in March 2022, to achieve an annual output of 25,000 tons of silicon steel, the second phase of the project will cooperate with Wisco to develop more high-end brands, silicon steel production capacity is expected to reach 80,000 tons. After the full volume of the project, the transformer industry will achieve a larger scale and achieve a stronger competitive advantage with the high-quality development of the manufacturing industry. Secondly, our company has developed a core intelligent stacking machine after three years to improve the quality and efficiency of iron core stacking. Last year, our company introduced the industrial precision welding robot arm to improve the welding process of transformer oil tank and complete the welding work of transformer oil tank with high quality and quantity.

Finally, Hubang Power's new factory intelligent workshop will be ready to put into operation in 2024, to achieve the full line of intelligent production of transformers as much as possible, which will greatly improve the efficiency of transformer products and increase the quality of related products.

- Mission: Make power transmission safer and more energy efficient, and promote the development of China's high-end power equipment industry.

- Vision: To become a highly trusted power equipment manufacturer.

- Core values: scientific and technological innovation, unity and cooperation, continuous struggle, harmonious coexistence.

We’re a reliable partner that shapes our expertise into success for your project.

-

The oil-free design of dry transformers solves the risk of oil leakage

In oil-immersed transformers, insulating oil is used as a cooling and insulating...

READ MORE -

Arc extinguishing technology for arc resistance of dry transformer

In dry transformers, commonly used arc extinguishing technologies mainly include...

READ MORE -

The distribution of box-type substations should take into account local renewable energy resources

Considering local renewable energy resources in the distribution design of box-t...

READ MORE -

Reasonable site selection of box-type substations should take into account the location of the load center

When selecting a box-type substation, the location of the load center should be ...

READ MORE -

Setting up noise barriers for underground box-type substations

The setting up of noise barriers for underground box-type substations is a key m...

READ MORE -

Multifunctional integration advantages of underground box-type substations

Underground box-type substations have achieved deep integration of power facilit...

READ MORE

2.Advantages of Dry Type Power Transformers

3.Applications and Future Trends in Dry Type Power Transformers

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى